Feed Technologies

Feed Technologies

Feed Technologies - Products

Atlas Yem | Feed Milling, Flaking & Recycling Technology

Feed Technologies All Products

Industrial Feed Technologies: Global Production Standards

In the modern livestock industry, staying competitive requires the use of feed technologies that process raw materials with maximum efficiency. Atlas Yem provides energy-efficient and fully automated feed production plant solutions that meet global market demands. From industrial crushing systems to high-pressure pelletizing units, every stage is engineered to minimize operating costs and maximize final product quality.

Integrated Feed Mill Setup and Engineering Solutions

A feed mill is not just a collection of machines; it is a synchronized ecosystem. Atlas Yem engineering provides solutions that eliminate bottlenecks at every stage, from raw material intake to final packaging. In our turnkey feed mill projects, we combine heavy-duty manufacturing power with global technical standards to ensure 24/7 operational reliability.

Process-Oriented Sub-System Categories

We provide specialized services across 11 core sub-categories for every stage of your production line:

-

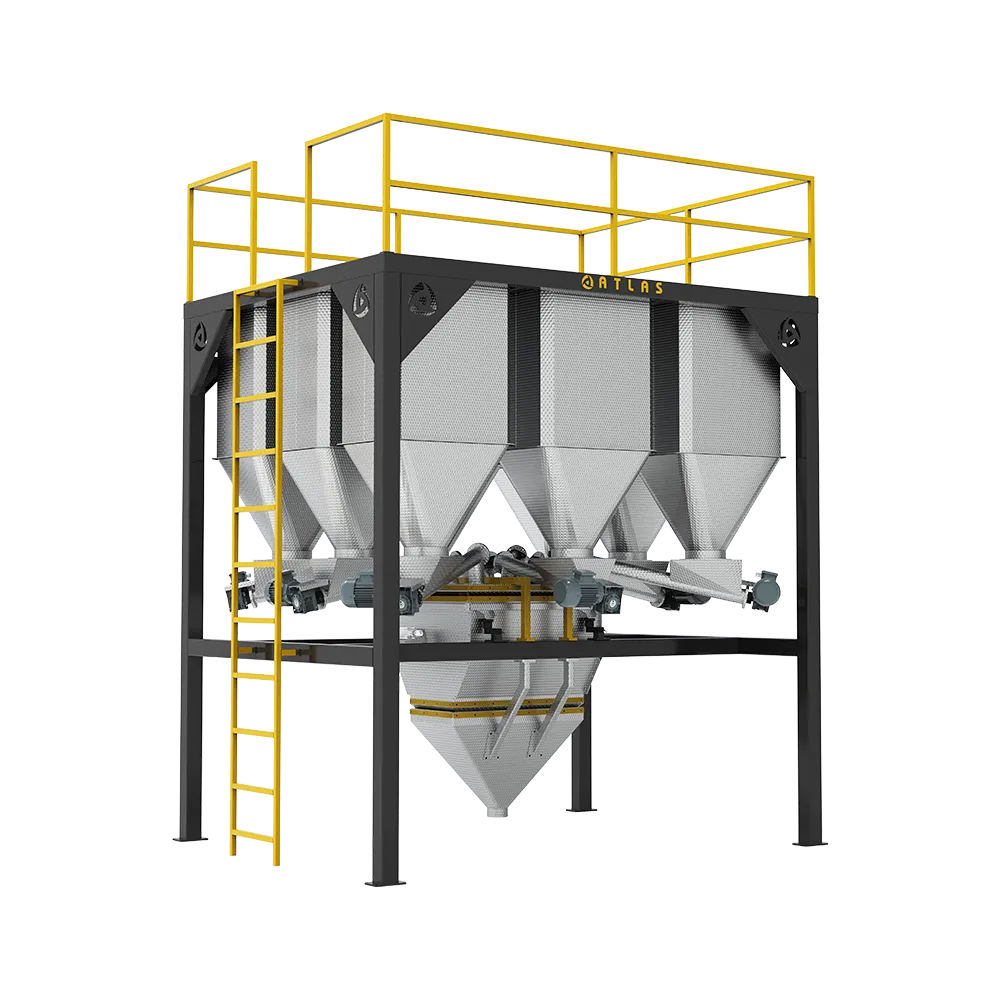

Raw Material Preparation: Precise ration preparation with Crushing and Dosing Systems.

-

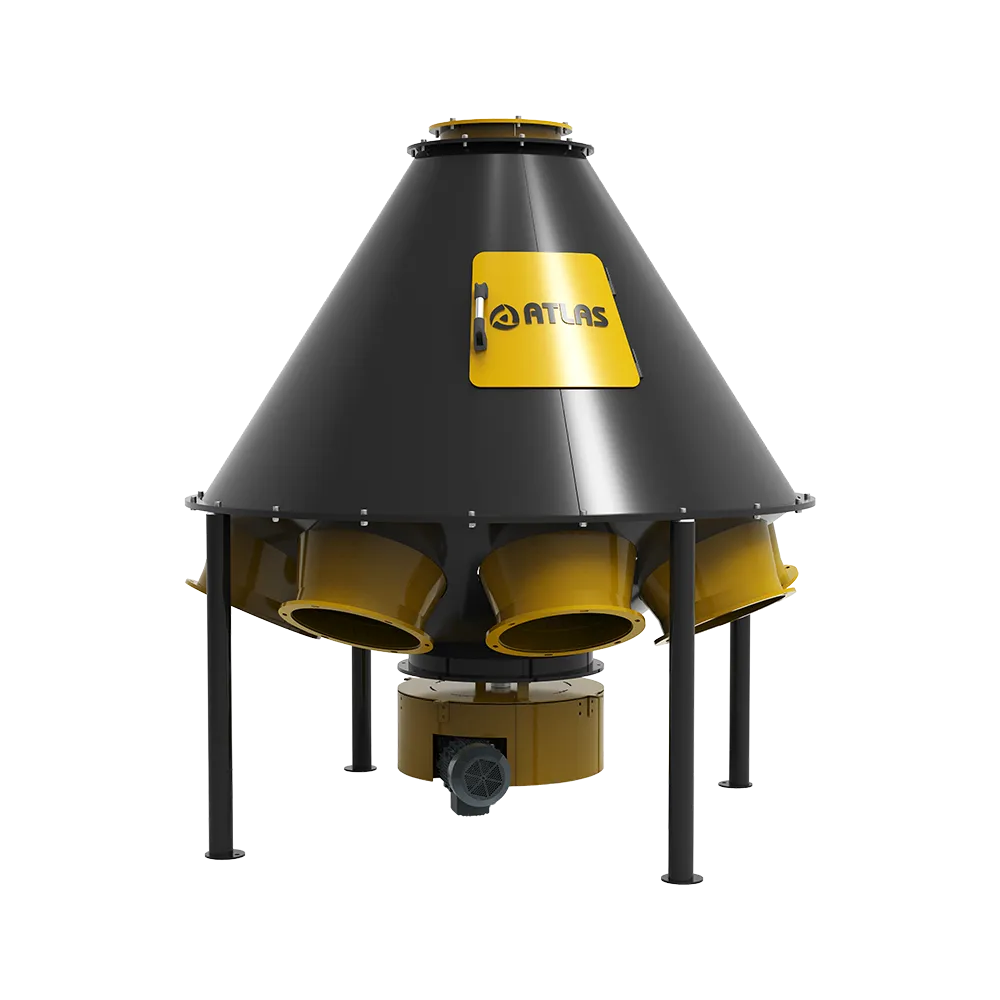

Process Line: Homogeneous content management with Mixing and Liquid Additive Equipment.

-

Forming and Quality: Pelletizing, Screening, and Ventilation (Cooling) Systems.

-

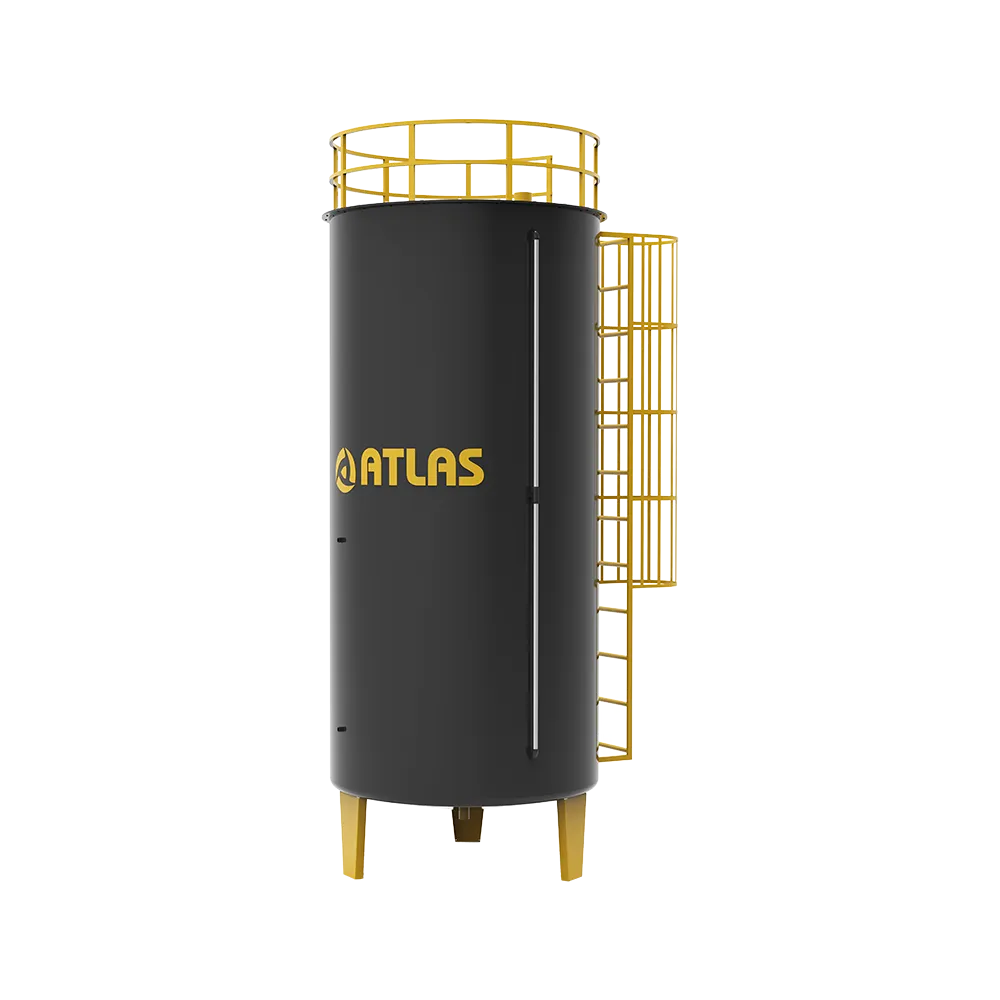

Logistics and Storage: Transport, Routing, Storage, and Packaging Units.

Why Atlas Yem Technologies?

Atlas Yem stands out from competitors through cost optimization and global engineering standards. Our systems maintain high precision in feed ration preparation, even in high-tonnage operations. Our feed machine technology, utilized in cattle, poultry, and pet food production lines, is equipped with long-life mechanical components and smart automation software.

Energy Savings and Operational Performance

Energy consumption is the largest overhead in feed production. We reduce these costs by up to 20% through the use of new-generation motor drives and optimized mechanical designs. During the feed plant installation process, we don't just sell machinery; we provide a technical partnership that focuses on reducing the cost per ton and shortening the equipment payback period.

179 from the product 13–24 Showing between