Pelletizing Systems & Feed Pellet Mill Models

Pelletizing Systems

Pelletizing Systems - Products

Atlas Yem | Feed Milling, Flaking & Recycling Technology

Pelletizing Systems All Products

Industrial Pelletizing Systems and Pellet Press Machines

Sustainable profitability in the feed industry begins at the intersection of low energy consumption and high product quality. The feed technologies we offer as Atlas Yem do more than just process raw materials; they provide engineering solutions that elevate them to the highest bioavailability levels. In our feed production plant projects, our focus is on minimizing operating expenses (OPEX) while ensuring the physical and nutritional standards that increase the market value of the final product.

Pelletizing Systems: Maximum PDI and Low Fines Ratio

Pellet Durability Index (PDI) directly affects the loss rate in logistics processes and the feed intake rate of animals. Atlas Yem pelletizing systems optimize the thermal and mechanical processing of the mash feed, allowing you to produce dust-free pellets with high digestibility. Our systems, showing high performance in cattle feed, poultry feed, and pet food production lines, are designed for 24/7 uninterrupted operation.

Pellet Press and Operational Durability

Our standard pellet press models offer stability even in high-tonnage production with heavy-duty body structures and optimized roller-die clearances. Thanks to heat-treated components, wear costs are reduced, and mechanical resistance against sudden load changes is maximized. As a leading feed pellet machine provider, we ensure that our equipment withstands the most demanding industrial environments.

Geared Pellet Press: Maximum Energy Efficiency

For facilities aiming to reduce energy costs, the geared pellet press (gearbox driven) we developed provides up to 15% more power transmission efficiency compared to belt-driven systems. The direct drive pellet mill structure eliminates belt slippage and friction losses, transferring the total motor power directly to the pelleting chamber. This translates into a tangible reduction in electricity costs per ton and shortens the payback period of your machinery investment.

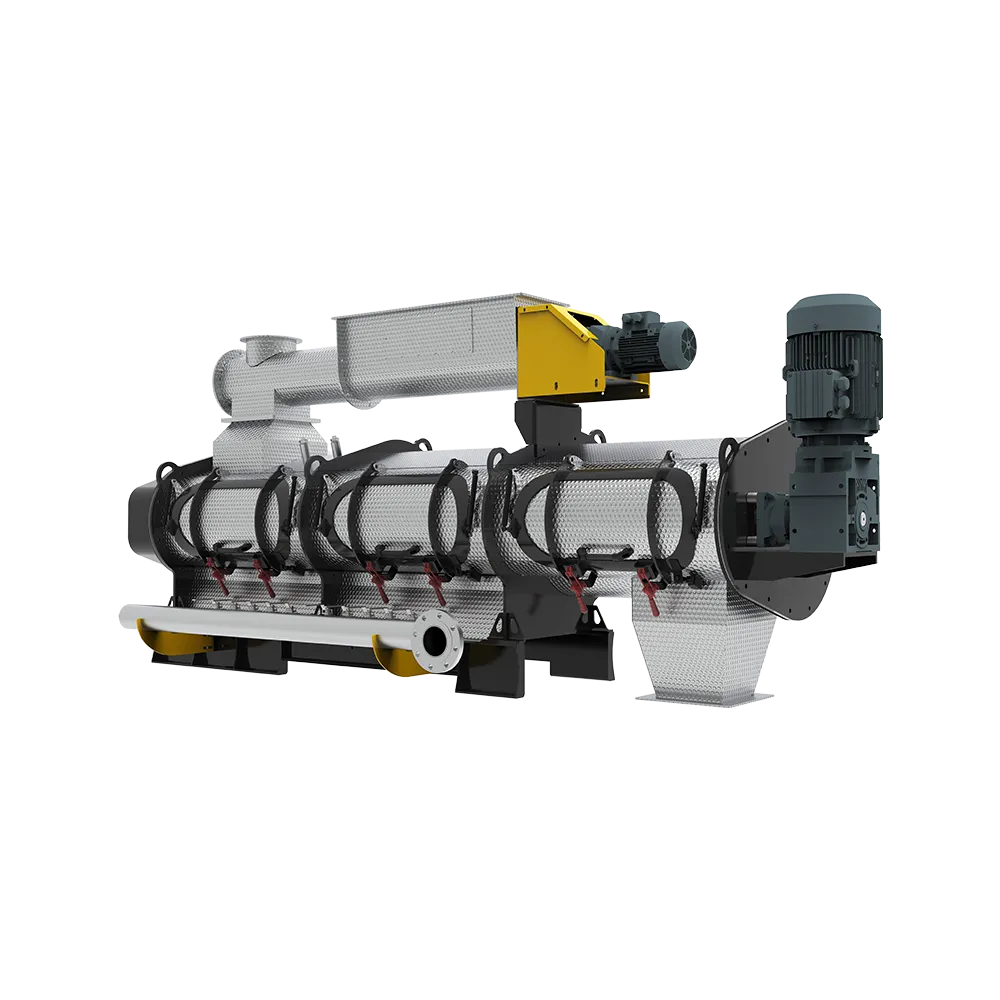

Feed Conditioner: Optimal Gelatinization and Hygiene

60% of pellet quality is determined during the conditioning stage. Atlas Yem conditioner units ensure that steam and heat penetrate the feed homogeneously, resulting in total starch gelatinization. Our steam conditioner systems eliminate pathogens to ensure the microbiological safety of the feed while extending the die life of the pellet mill.

Advanced Steam Conditioning and Retention Management

With its stainless steel internal structure and adjustable paddle angles, the retention time is managed precisely according to the type of ration. Whether it is a single shaft conditioner or a double shaft conditioner, Atlas Yem technology ensures the feed reaches the ideal temperature and moisture levels before entering the pellet press, guaranteeing superior durability and animal performance.

14 from the product 13–14 Showing between